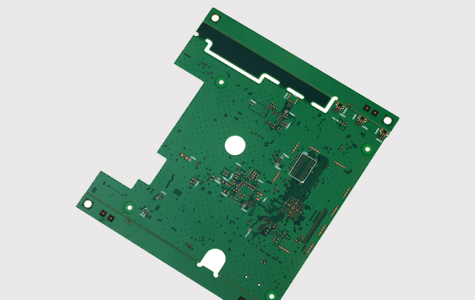

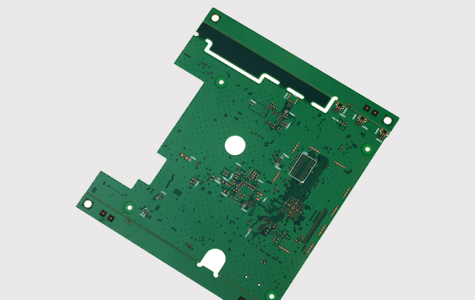

WHAT IS FR4 PCB?

- Author:Admin

- Time:2023-05-27

- Browse:

FR4 PCB refers to a type of printed circuit board (PCB) made from a specific grade of fiberglass-reinforced epoxy laminate material known as FR4. FR4 is the most widely used PCB material due to its excellent electrical and mechanical properties.

The term "FR4" is derived from the NEMA grade designation for the material, where "FR" stands for "fire retardant" and "4" refers to the specific resin system used. The resin in FR4 is flame retardant, making it self-extinguishing and offering a certain level of fire resistance.

FR4 PCBs are known for their high strength, rigidity, and dimensional stability. They provide good electrical insulation, high mechanical strength, and resistance to moisture, chemicals, and temperature variations. These properties make FR4 PCBs suitable for a wide range of applications, including consumer electronics, telecommunications, industrial equipment, automotive electronics, and more.

The FR4 material is used as the substrate or base material for the PCB, onto which copper traces and components are mounted. The fiberglass reinforcement provides mechanical support and stability to the board, while the epoxy resin acts as an insulator between the copper layers and components.

Overall, FR4 PCBs are popular due to their reliability, cost-effectiveness, and versatility, making them a standard choice for many electronic devices and industries

The term "FR4" is derived from the NEMA grade designation for the material, where "FR" stands for "fire retardant" and "4" refers to the specific resin system used. The resin in FR4 is flame retardant, making it self-extinguishing and offering a certain level of fire resistance.

FR4 PCBs are known for their high strength, rigidity, and dimensional stability. They provide good electrical insulation, high mechanical strength, and resistance to moisture, chemicals, and temperature variations. These properties make FR4 PCBs suitable for a wide range of applications, including consumer electronics, telecommunications, industrial equipment, automotive electronics, and more.

The FR4 material is used as the substrate or base material for the PCB, onto which copper traces and components are mounted. The fiberglass reinforcement provides mechanical support and stability to the board, while the epoxy resin acts as an insulator between the copper layers and components.

Overall, FR4 PCBs are popular due to their reliability, cost-effectiveness, and versatility, making them a standard choice for many electronic devices and industries

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...