Through Hole PCB Assembly Services

- Author:Admin

- Time:2024-01-11

- Browse:

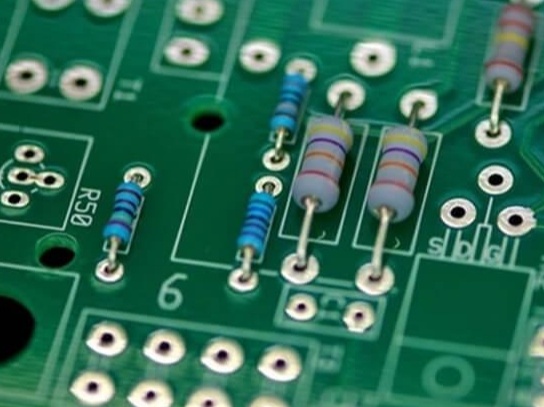

What is through-hole assembly?

Until around 1980, through-hole assembly was the dominant method of PSB assembly, although the use of SMT began as early as around 1960. (You'll learn more about SMT in my next guide in this series.) Through-hole PCB assembly is the process of mounting through-hole components onto a bare printed circuit board (PCB). Through-hole technology (THT) involves soldering a component to a board with its leads passed through drilled holes in the board. The leads are soldered to the pads on the back, either manually (hand placement) or using an automatic insertion machine

Advantages of through-hole assembly:

1. Easier to prototypeThrough-hole components are easy to replace; therefore they are ideal for PCB prototyping and testing.

2. High heat resistance

THT keys have high heat resistance; thus making them preferred for aerospace and military products

3. Better power handling capabilities

Soldering through-hole components creates a strong bond between the circuit board and the component. Therefore, it is ideal for larger components that are bound to be affected by:

4. Stronger physical connections

The leads of THT components have stronger physical endurance. They can withstand environmental stress because they are soldered on opposite sides of the circuit board (they go through the circuit board) for a stronger physical connection, which is why THT is the first choice for stadium and billboard LED lights. It is also used in industrial equipment and machinery due to exposure to very harsh conditions

Disadvantages of through-hole assembly

1. Longer production time

It takes a lot of time to drill the multiple holes that the leads are expected to pass through.

2. Expensive

Since the drilling process is difficult and time-consuming, it increases production costs and minimizes space on the circuit board - drilling holes in the surface of the circuit board limits the routing area for trace signals.

Also, by running the leads through the board, only one side of it is available, making the THT PCB slightly slower

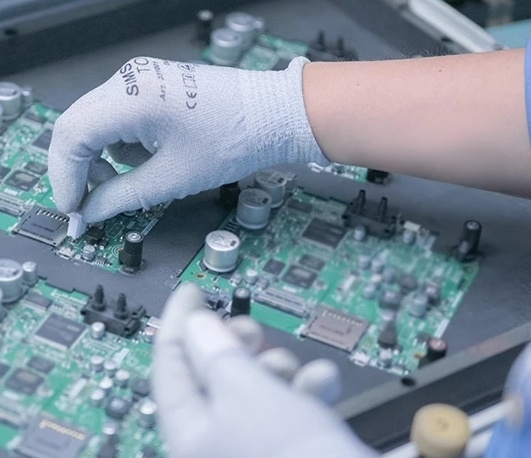

Our Through-Hole PCB Assembly Services

Different applications demand different through-hole technology equipment. To better serve our diverse group of clients, Semshine has invested in some of the most advanced soldering and assembly tools on the market today. We are fully qualified to manufacture printed circuit board assemblies to the IPC-A-610 requirement in both leaded and RoHS specifications.

Depending on your project needs, we can provide either fully automated through-hole assembly or semi-automated through-hole assembly services for runs of up to 50,000 units.

Thanks to our production capabilities, we are often brought in at the prototyping stages of a project. However, we also perform electronic contract manufacturing and testing as necessary. Our clients include government contractors and private manufacturers, all of whom count on Semshine for fast turnaround times, excellent customer service and industry-leading engineering expertise. We are happy to provide initial consultations by phone or email or to meet with you in person.

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...