china turnkey pcb assembly,China turnkey pcb assembly manufacturers

- Author:Admin

- Time:2023-12-26

- Browse:

China turnkey pcb assembly manufacturers

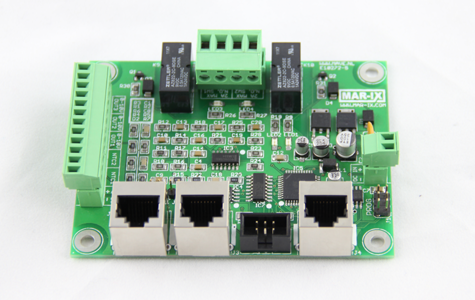

china turnkey pcb assembly,China turnkey pcb assembly manufacturers,17 Years with PCB Solution,60000 Square Meters Month Capability,600 Customers in Worldwide,Our factory is fully compliant with the standards of IPC Class 6012B. All the products are certificated with UL, REACH, RoHS, and ISO.

Shenzhen Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.

Up to now, Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

With rich experience and expertise, Semshine is your go-to choice for a China PCB manufacturer. We are looking forward to establishing a long-term cooperative relationship with you.

What is turnkey PCB assembly?

turnkey PCB assembly refers to the turnkey PCB assembly method provided by PCBA manufacturers for material purchase, PCB production, SMT patch processing, DIP plug-in processing, PCBA testing, finished product assembly, customs clearance and international logistics. Companies that need PCBA processing services only need to provide design solutions, and they can sit and wait for complete products, in addition, PCBA factories can also provide PCB copying services. SMT chip processing is only a part of PCBA one-stop service, PCBA processing manufacturers will provide separate SMT chip processing services. The PCBA processing mode is better than the SMT patch processing mode and has stronger survival ability.

Why Choose Us

1. The customer does not need to spend any time and effort, just provide one or two sets of functional samples that need to be copied, and be responsible for accepting the functional prototype cloned by our company;

Under normal circumstances, the single-panel design and dual-panel design are completed within 1 day, the four-layer board design is completed within 2 days, and the six-to-ten-layer board design is completed within 3 days, and the specific PCB design cycle depends on the specific requirements.

High responsibility PCB design team, powerful PCB design software combined with strict PCB design process can ensure that PCB design success, 100% accuracy, thereby shortening product development cycle and reducing product development costs.

The professional PCB design evaluation team gives a reasonable quotation according to the specific requirements of customers. In addition, our company has launched many valuable return customer package plans for old customers.

3. We have rich experience in PCB design

Our successfully designed products cover today's major electronics sectors: chip companies, communications, industrial control, automotive electronics, aerospace, scientific research, medical, consumer electronics and others. In particular, he has rich experience in simulation and PCB design in the fields of high-frequency PCB, high-speed PCB, PCB signal integrity simulation and analysis, and digital-analog A/D hybrid circuit board design.

4. Comprehensive quality management

We not only focus on advanced technology, but also the quality management of the entire production process of PCB, including excellent product design, high-quality materials, suitable equipment, mature production technology, skilled production personnel and strict and meticulous inspection, storage and packaging

5. Strong overall strength

We can provide a full range of services including PCB design, prototype debugging, component procurement, high-precision board making, SMT patch processing, etc., and can design the products that customers need according to customer requirements, including the functional improvement of existing products and the secondary development of technical optimization.

6. Perfect post-service system

External: Adhere to the "customer first" service purpose, customer service phone 24 hours online, for you to solve problems. If necessary, technicians provide on-site technical services to ensure that users' products can be used normally and effectively and maintain certain contact with customers, pay attention to the use of products, etc.

Internal: accurate and timely feedback on the use of products, quality information and a variety of important social information, for enterprises to make correct decisions in a timely manner, and better serve our customers.

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...