FR-4 pcb manufacturing companies in GD(Grenada)

- Author:Admin

- Time:2023-11-11

- Browse:

Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

WHAT IS FR4 PCB?

FR4 PCB refers to a type of printed circuit board (PCB) made from a specific grade of fiberglass-reinforced epoxy laminate material known as FR4. FR4 is the most widely used PCB material due to its excellent electrical and mechanical properties.

The term "FR4" is derived from the NEMA grade designation for the material, where "FR" stands for "fire retardant" and "4" refers to the specific resin system used. The resin in FR4 is flame retardant, making it self-extinguishing and offering a certain level of fire resistance.

FR-4 VIDEOS

Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.Types of FR-4 PCB Material

There are four different types of FR-4 material available in the market based on individual properties, they are listed:

Standard FR-4

Standard FR-4 refers to the normal material, with heat resistance ranging from 150-160 Celsius.

High CTI FR-4

The Comparative Tracking Index is the limit to which the FR-4 or any other insulating material can resist the unwanted current flowing between the tracks on the printed circuit board. The CTI value indicates how resistive PCB base material is against unpleasant environmental and electrical conditions such as moisture and leakages on board. The high CTI material with a maximum value of 600 voltages ensures that the base is more resistant and can withstand harsh environmental and electrical conditions.

High TG FR-4

High TG FR-4 stands for high glass transition temperature. PCBs made with high glass transition temperature FR-4 material have the ability to resist and maintain their shape at a temperature of 170 ℃. In this type of base material, Higher TG is achieved through extra-efficient lamination. PCBs made with high TG FR-4 material have the ability to resist and maintain their shape at a temperature of 170 ℃. The standard Fr-4 material is a great insulator and flame retardant, but still, it has some limits when exposed to high power, voltage, or heat. If a certain limit exceeds, the materials insulating properties can get weakened. It can start conducting electricity instead of insulating it. Thereby high Tg FR-4 is used to avoid these unwanted circumstances.

FR-4 with no laminated Copper

This type of FR-4 is a little different with distinct functions. As the name itself explain that this type of material has no copper lamination on it and, therefore, is used to insulate and support other boards, etc.

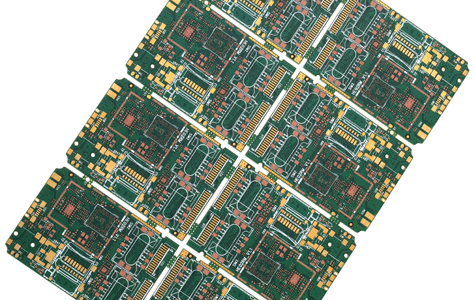

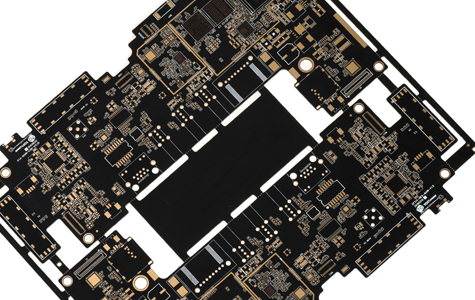

FR4 PCB Products

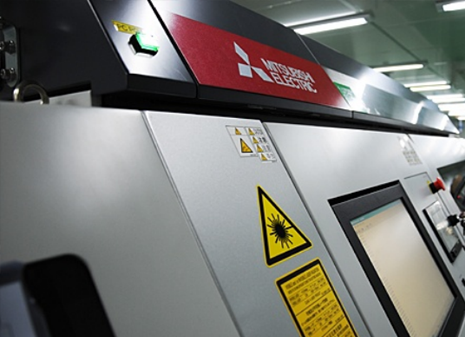

FR4 PCB Workshop

fr4 substrate parameters

Other attributes

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...